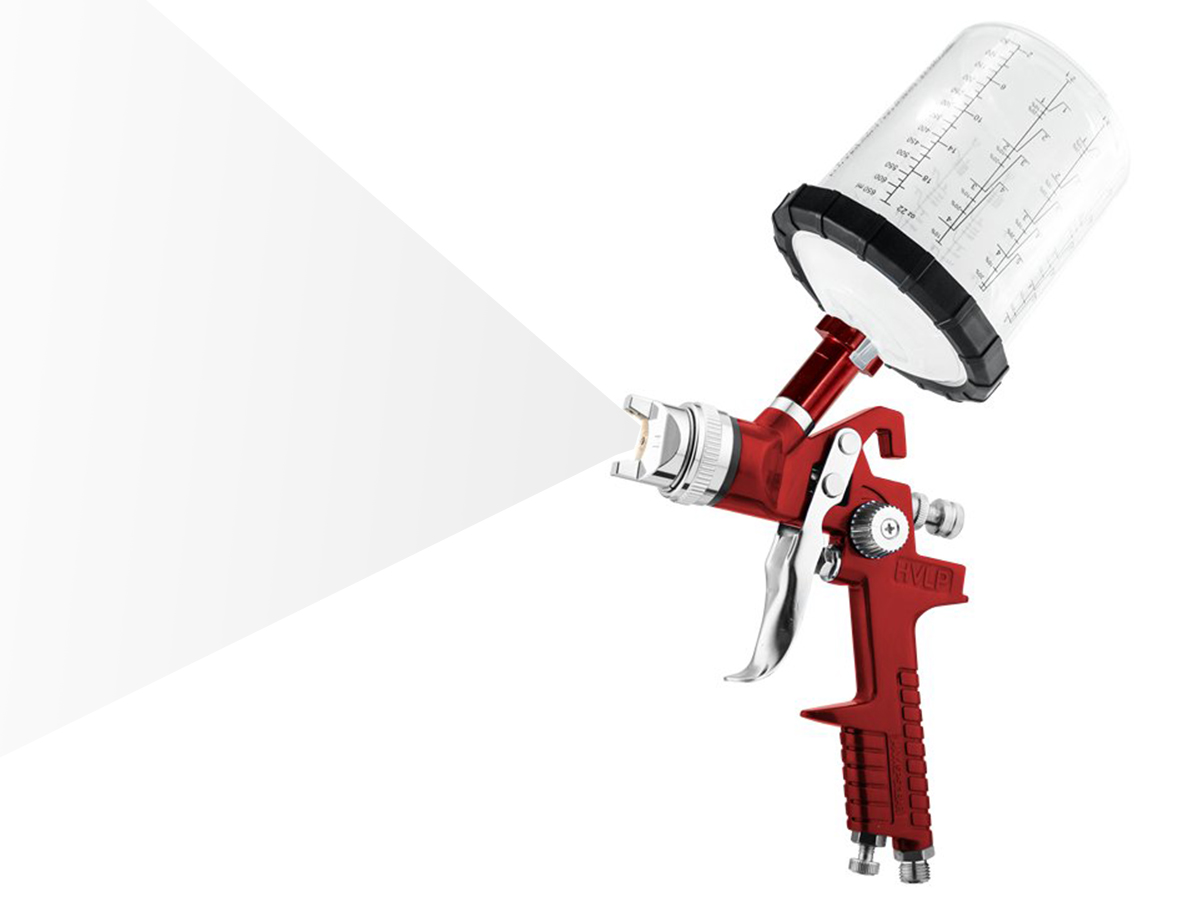

When a paint spray gun experiences the issue of only blowing air but not spraying paint, possible reasons and corresponding solutions are as follows:

Possible Reasons:

1.Nozzle Clogging:

The nozzle of the spray gun may be clogged due to impurities in the paint or prolonged disuse, preventing the paint from being sprayed smoothly.

2.Poor Sealing:

Insufficient sealing between the various components of the spray gun, such as between the nozzle and the gun body or at the straw head, can lead to air leakage, weakening the siphon effect and making it impossible to draw and spray paint.

3.Insufficient Air Pressure:

The air pressure setting of the spray gun may be insufficient, or the air source may be unstable, resulting in the spray gun being unable to generate sufficient suction to draw paint.

4.Paint Issues:

The viscosity of the paint, whether too high or too low, can cause the spray gun to malfunction. Excessively high viscosity makes the paint difficult to flow, while excessively low viscosity may cause paint leakage within the spray gun.

Solutions:

1.Clean the Nozzle:

Remove the nozzle and thoroughly clean it and the interior of the spray gun using a diluent or specialized cleaning agent to ensure no impurities remain. After cleaning, use clean compressed air to dry the nozzle and spray gun.

2.Check and Enhance Sealing:

Inspect the sealing condition between the various components of the spray gun, especially between the nozzle and the gun body and at the straw head. If air leakage is detected, promptly replace the seals or adjust the sealing structure.

3.Adjust Air Pressure:

Check the air pressure setting of the spray gun to ensure it is within a reasonable range. If the pressure is insufficient, try increasing it or check the stability of the air source.

4.Adjust Paint Viscosity:

Use a viscometer to measure the viscosity of the paint and adjust it to the appropriate range as needed. Generally, the viscosity of the paint should be controlled within the range recommended by the spray gun manufacturer.

Additional Checks:

Examine other components of the spray gun, such as the trigger and adjustment valve, for damage or malfunctions. If any are found, promptly replace or repair them.

If none of the above methods resolve the issue, it may indicate a more severe fault with the spray gun itself. It is recommended to contact professional technicians for inspection or replacement.

Precautions:

When troubleshooting spray gun issues, always ensure the air and power sources are turned off for safety.

When using diluents or cleaning agents, wear protective gear to avoid direct skin contact.

Follow the manufacturer’s instructions when cleaning and maintaining the spray gun to prevent damage or affecting its performance.

What to do if the paint spray gun only blows air but does not spray paint?

2024-09-06