When selecting a nozzle type for your spray gun, the primary consideration lies in the combination of the nozzle and the air cap, which constitute the core components of a manual spray gun. The air cap determines the shape of the spray pattern (such as flat, round, hollow conical, etc.), crucial for achieving optimal spraying results. We proudly employ precision machining processes to manufacture a full range of nozzles within our own factory, ensuring stable flow rates and consistent spray patterns. The nozzles are crafted from high-quality materials like stainless steel and tungsten carbide, designed to extend their lifespan and cater to continuous production demands.

Choosing the right nozzle size requires comprehensive consideration of:

Coating Characteristics: Firstly, assess the thickness of the coating to be sprayed. Thicker coatings (like primers) typically require nozzles with larger apertures, such as 1.7 or 1.8 millimeters, to ensure adequate coverage and even spraying. In most cases, painters select aperture sizes within the range of 1.2 to 2.0 millimeters, unless special professional applications are involved.

Surface Area of Application: Secondly, consider the size of the surface area to be sprayed. This directly relates to the desired fan width, i.e., the atomization range of the paint as it leaves the nozzle. Airless spray guns, due to their lack of air atomization, offer more precise control over fan width, making them suitable for large areas like shipbuilding projects. A wide fan can increase coverage efficiency and reduce paint build-up. For smaller areas, narrow fan nozzles are preferable to minimize overspray and ensure concentrated paint application that is less prone to flaking.

Tips for Choosing Nozzle Size Based on Application:

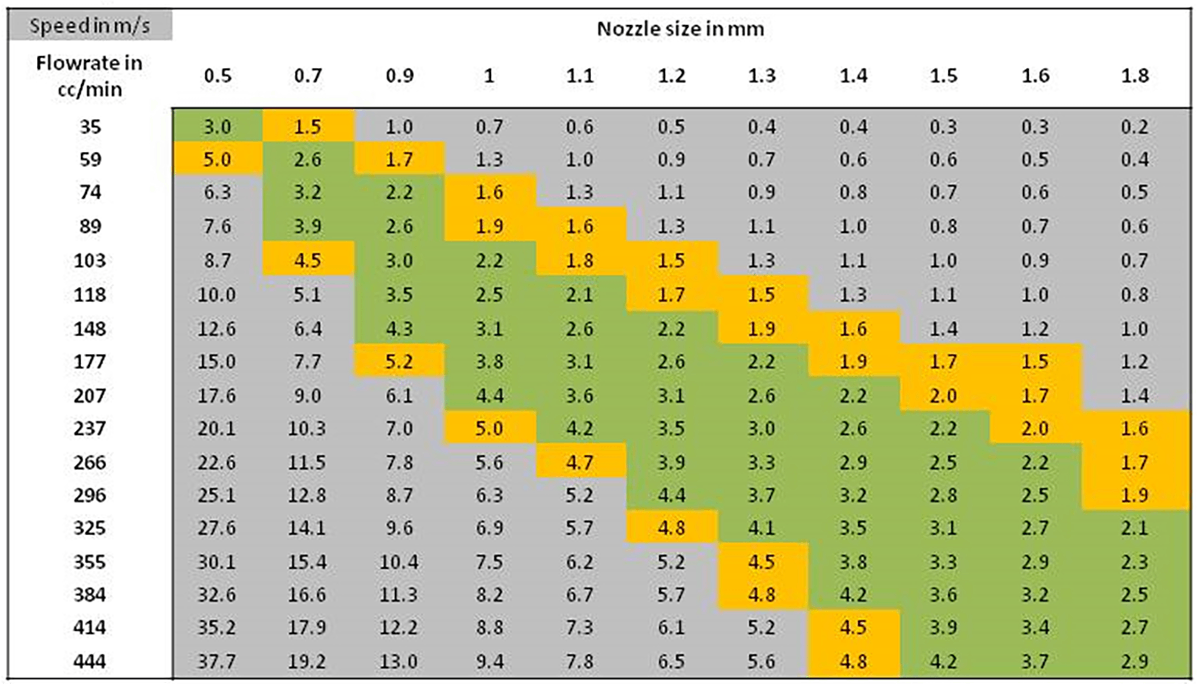

For air spray systems, optimal spray quality is achieved when the paint particle velocity falls within the range of 1.5m/s to 5m/s. Consult charts and select the most suitable nozzle size (e.g., 0.9 or 1.0 millimeters) based on specific flow rates (e.g., 120cc/min).

We also provide nozzle size recommendations covering most common paint applications:

0.8 millimeters: Ideal for delicate spraying tasks, such as thin coatings or masking operations.

1.2 millimeters: Suitable for fine finishes, clear coats, and wood toning.

1.4 millimeters: A versatile choice for clear coats, primers, or single-layer paints.

1.6 millimeters: Applicable to most medium-viscosity paints, but caution should be taken to avoid orange peel effects on thin coatings.

1.8 millimeters: The ideal choice for quick application of primers.

2.2-2.5 millimeters: Designed specifically for resins, gel coats, and thicker coatings.

Secrets to Prolonging Nozzle Lifespan:

Strictly prohibit the use of metal tools to clean nozzles to prevent damage.

Thoroughly clean the nozzle and spray gun after each use, using a soft-bristled brush for gentle cleaning.

If using gritty paint, filter it first to reduce impurities.

Always apply the lowest effective pressure during spraying to avoid excessive wear.

Maintain an appropriate spraying distance, generally recommended as 8 to 12 inches, to ensure optimal spraying results and extend nozzle life.

Remember, high-quality paint not only enhances surface appearance but also indirectly prolongs nozzle lifespan, offering double benefits to your spraying operations.