HVLP Spray Gun and Air Compressor Selection Guide

HVLP (High Volume Low Pressure) spray technology, since its introduction by the US Environmental Protection Agency (EPA) in the 1970s, has been renowned for its exceptional environmental benefits and efficient paint utilization. This technology requires a minimum of 65% paint transfer efficiency, significantly reducing paint waste. Additionally, the maximum pressure at the air cap is limited to 0.7bar/10psi, effectively preventing air pollution issues that can arise from traditional spray guns. The HVLP spray gun stands as a prominent representative of this technology, achieving both efficiency and environmental protection through fine atomization of paint using high volume rather than high-pressure air.

HVLP Spray Gun: A Paragon of Environmental Protection and Efficiency

As its name suggests, the HVLP spray gun adheres to the design principle of high volume and low pressure. Here, “HV” represents the smooth flow of high-volume air from the air cap, while “LP” signifies the maintenance of low air pressure at the gun handle. This design revolutionizes the traditional 3.5bar high-pressure atomization model of spray guns, adopting a gentler 0.7bar pressure. This not only minimizes the dispersion of paint into the air but also ensures that more paint adheres precisely to the work piece surface, thereby achieving higher paint utilization and lower costs.

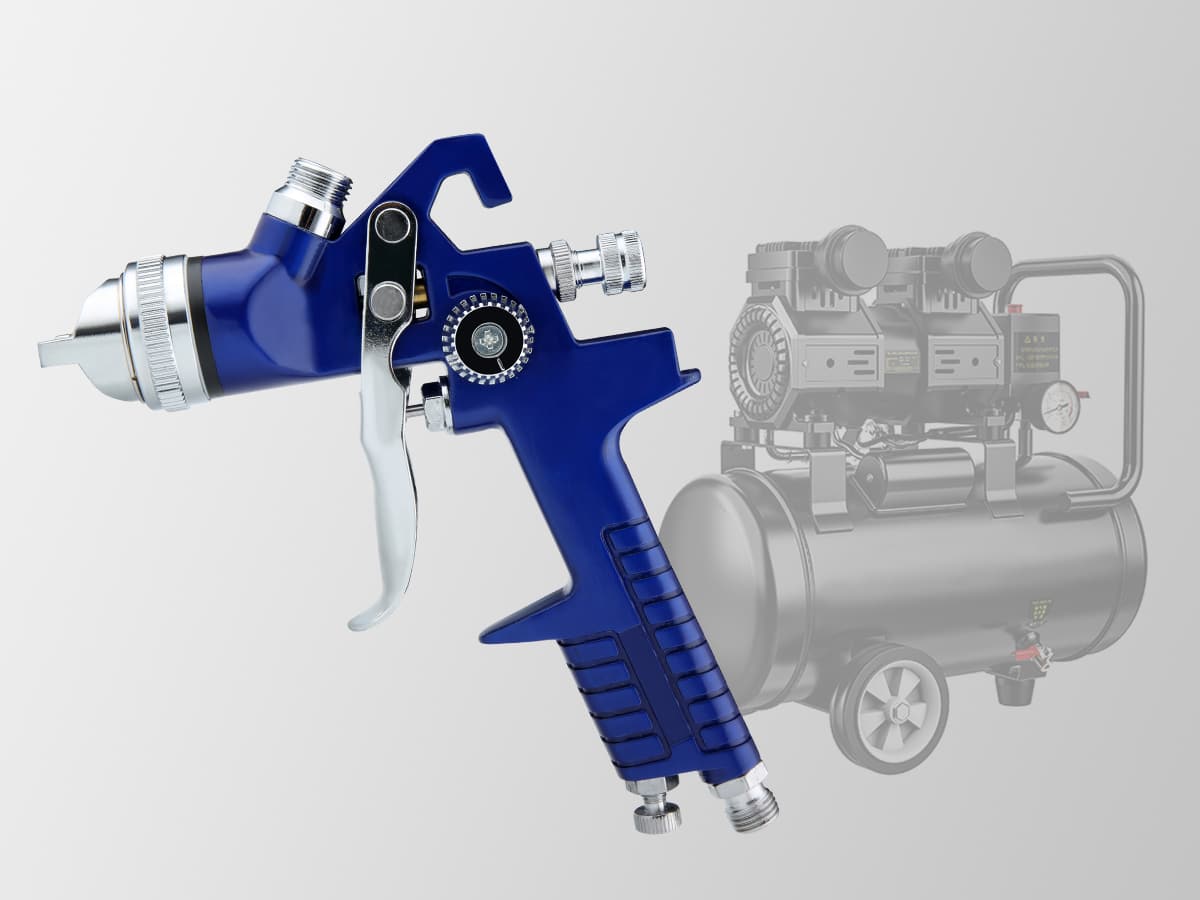

Key Points for Selecting a Compatible Air Compressor

To fully leverage the advantages of HVLP spray guns, selecting the right air compressor is crucial. Given the HVLP technology’s demand for significant air volume, it is recommended to choose an air compressor with a power rating of at least 2.5-3 HP, equipped with a 75-liter pressure tank. This configuration ensures a continuous and stable supply of compressed air, meeting the requirements for efficient paint atomization. Furthermore, to maintain air quality, an oil-water separator should be installed to remove impurities from the compressed air. If opting for a traditional air compressor, a pressure regulator is also necessary for precise control of air pressure.

SPURUI HVLP Spray Gun Series: Innovation Leading the Future

Drawing on 22 years of experience in the traditional air spray gun industry, SPURUI has successfully launched its self-developed HVLP spray gun series. This series not only inherits the efficiency and environmental protection characteristics of HVLP technology but also gains widespread market recognition for its lightweight design and high-precision spraying capabilities. Whether it’s the pressure-feed or gravity-feed design, these spray guns can effortlessly tackle various delicate spraying tasks, ensuring that paint adheres to the work piece surface in optimal condition while reducing over spray and air pollution, meeting the strictest environmental requirements.

HVLP spray guns, with their unique technological advantages and environmental philosophy, are gradually becoming the preferred tool in the modern painting industry. Choosing the right air compressor as a companion device not only maximizes the performance benefits of HVLP spray guns but also further enhances work efficiency and paint utilization. The SPURUI HVLP spray gun series, with its outstanding performance and reliable quality, provides users with more efficient and environmentally friendly painting solutions.